A multi-axis load cell is one of the most important tools in modern engineering, manufacturing, robotics, and research. Right from the start, a multi-axis load cell helps measure forces and moments in more than one direction at the same time. Instead of guessing how forces behave in real life, engineers rely on this smart device to get accurate, real-world data. Simply put, it tells us how things push, pull, twist, and bend all in one go.

This article is a fully detailed, easy-to-understand, and trustworthy guide about the multi-axis load cell. Written in clear Grade 7 English, it explains what it is, how it works, where it’s used, and why it matters. Along the way, you’ll see examples, bullet points, and a helpful table to make learning smooth and enjoyable.

Understanding What a Multi-Axis Load Cell Is

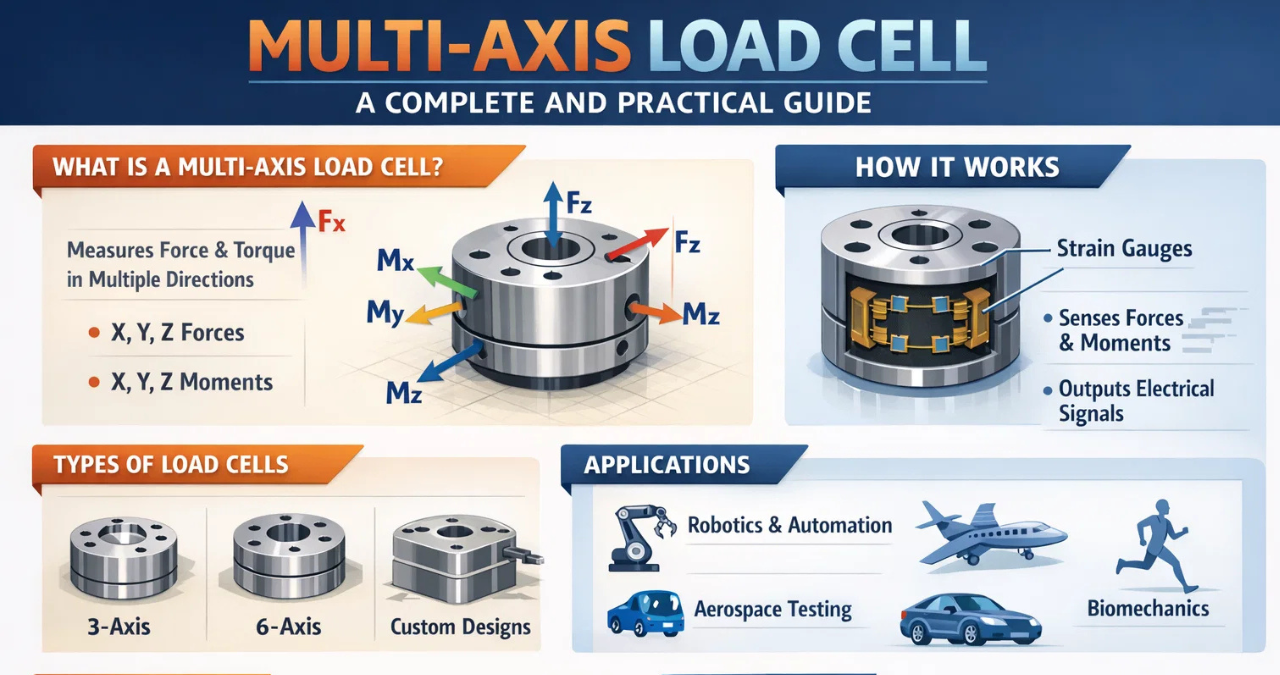

A multi-axis load cell is a sensor that measures force in multiple directions at the same time. Traditional load cells usually measure force along just one line, often called a single axis. A multi-axis load cell, however, measures forces along two, three, or even six axes.

In real-world situations, forces rarely act in only one direction. Machines vibrate, tools twist, and structures experience complex loads. That’s where a multi-axis load cell shines it captures the full picture.

At its core, a multi-axis load cell converts mechanical force into an electrical signal. This signal is then analyzed by computers or controllers to show exact force values.

Why Multi-Axis Load Cell Technology Matters Today

The world is moving fast, and technology is getting smarter every day. A multi-axis load cell plays a big role in making systems safer, more accurate, and more efficient.

Here’s why it matters so much:

- It improves product quality by giving precise force data

- It helps prevent mechanical failures before they happen

- It supports innovation in robotics and automation

- It reduces trial-and-error testing, saving time and money

In short, a multi-axis load cell helps engineers work smarter, not harder.

How a Multi-Axis Load Cell Works in Simple Terms

A multi-axis load cell may sound complex, but the idea behind it is quite simple.

Inside the load cell, there is a specially designed metal structure. When force is applied, this structure bends slightly so slightly that you can’t see it. Strain gauges attached to the structure detect this tiny movement.

Here’s the process in plain language:

- Force is applied to the load cell

- The internal structure deforms a little

- Strain gauges sense the deformation

- Electrical signals change based on the force

- The system calculates force values for each axis

Thanks to clever design, a multi-axis load cell can tell which direction the force is coming from and how strong it is.

Types of Multi-Axis Load Cell Designs

Not all multi-axis load cell designs are the same. Different applications need different shapes, sizes, and force ranges.

Some common types include:

- Two-axis load cells for simple horizontal and vertical forces

- Three-axis load cells for X, Y, and Z force measurement

- Six-axis load cells for full force and torque measurement

Six-axis models are especially popular in robotics and aerospace because they measure:

- Forces along X, Y, and Z

- Moments (torques) around X, Y, and Z

Each design balances strength, sensitivity, and accuracy in its own way.

Key Components Inside a Multi-Axis Load Cell

A multi-axis load cell may look like a solid block of metal, but inside, it’s a clever mix of science and engineering.

Main components include:

- Elastic body that deforms under load

- Strain gauges bonded to the elastic body

- Wiring and connectors for signal output

- Protective housing to guard against dust and moisture

All these parts work together to ensure the multi-axis load cell delivers reliable and repeatable data, even in tough conditions.

Applications of a Multi-Axis Load Cell Across Industries

The beauty of a multi-axis load cell is its versatility. It’s used in many industries, each with unique needs.

Common applications include:

- Robotics for force feedback and precision control

- Aerospace for structural testing and flight simulation

- Automotive testing for crash analysis and suspension systems

- Medical devices for rehabilitation and prosthetics

- Manufacturing for quality control and assembly

Wherever forces act in more than one direction, a multi-axis load cell fits right in.

Role of Multi-Axis Load Cell in Robotics and Automation

In robotics, precision is everything. A multi-axis load cell gives robots a sense of touch, allowing them to react to their environment.

For example:

- Robots can grip objects without crushing them

- Assembly robots can detect misalignment instantly

- Collaborative robots can work safely with humans

Without a multi-axis load cell, robots would be blind to complex forces. With it, they become smarter, safer, and more adaptable.

Benefits of Using a Multi-Axis Load Cell

Using a multi-axis load cell brings many advantages, and that’s no exaggeration.

Key benefits include:

- Accurate measurement of real-world forces

- Reduced need for multiple single-axis sensors

- Better understanding of system behavior

- Improved safety and reliability

- Long-term cost savings

When engineers use a multi-axis load cell, they gain confidence in their data and confidence leads to better decisions.

Challenges and Limitations of Multi-Axis Load Cell Systems

Even though a multi-axis load cell is powerful, it’s not magic. Like all tools, it has limits.

Some common challenges are:

- Higher cost compared to single-axis load cells

- More complex calibration process

- Sensitivity to temperature changes

- Need for careful installation and alignment

The good news is that modern designs and smart software help reduce these issues. With proper handling, a multi-axis load cell performs exceptionally well.

Choosing the Right Multi-Axis Load Cell for Your Needs

Picking the right multi-axis load cell isn’t about guessing. It’s about matching the sensor to the job.

Important factors to consider:

- Maximum force and torque ranges

- Number of axes required

- Accuracy and resolution

- Environmental conditions

- Mounting and size constraints

Taking the time to choose wisely ensures the multi-axis load cell delivers the best results for years to come.

Calibration and Accuracy in Multi-Axis Load Cell Measurement

Accuracy is the heart of any multi-axis load cell system. Calibration makes sure the sensor’s output matches real-world forces.

Calibration usually involves:

- Applying known forces in each direction

- Recording sensor outputs

- Creating correction factors

- Verifying results over time

Regular calibration keeps measurements trustworthy and maintains confidence in the data.

Maintenance and Care of a Multi-Axis Load Cell

A multi-axis load cell is a precision instrument, not a rough tool. Treating it well extends its life and performance.

Best practices include:

- Avoiding overload conditions

- Keeping connectors clean and dry

- Storing properly when not in use

- Scheduling regular inspections

A little care goes a long way, and it keeps the multi-axis load cell working like a charm.

Comparison Table: Single-Axis vs Multi-Axis Load Cell

| Feature | Single-Axis Load Cell | Multi-Axis Load Cell |

|---|---|---|

| Direction Measurement | One direction | Multiple directions |

| Complexity | Simple | Advanced |

| Cost | Lower | Higher |

| Data Detail | Limited | Comprehensive |

| Common Use | Basic weighing | Robotics, testing, research |

This table clearly shows why a multi-axis load cell is the better choice for complex force measurement.

Future Trends in Multi-Axis Load Cell Technology

The future of the multi-axis load cell looks bright and exciting. As technology improves, these sensors are becoming smaller, smarter, and more affordable.

Emerging trends include:

- Integration with AI and machine learning

- Wireless data transmission

- Higher accuracy with lower noise

- Improved materials for durability

These advances will make the multi-axis load cell even more valuable across industries.

Why Engineers Trust the Multi-Axis Load Cell

Trust isn’t built overnight, but the multi-axis load cell has earned it. Engineers rely on it because it delivers consistent, accurate, and meaningful data.

It turns complex force interactions into clear numbers. It supports innovation without cutting corners. And most importantly, it helps keep systems safe and reliable.

Final Thoughts on Multi-Axis Load Cell Technology

To wrap it all up, the multi-axis load cell is a powerful, reliable, and essential tool in today’s technical world. From robotics and aerospace to manufacturing and healthcare, it helps measure what truly matters real-world forces acting in multiple directions.

With its ability to improve accuracy, boost safety, and support innovation, the multi-axis load cell isn’t just a sensor; it’s a smart investment in better engineering. As technology continues to grow, the role of the multi-axis load cell will only become more important, making it a cornerstone of modern measurement and design.

In the end, choosing and using the right multi-axis load cell means clearer insights, stronger systems, and a future built on precision and trust.

You may also read

Toni Breidinger Husband: The Full Truth About Her Love Life, Relationships, and Future Plans